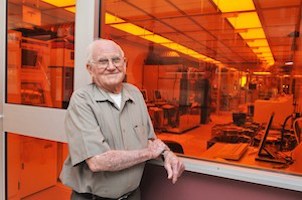

Willis Whitfield, 2008 outside of a clean room at Sandia National Lab’s Microsystems Engineering Sciences & Applications complex.

As readers may have noticed, we’ve started a new series we’re calling The Evolution of Technologies, which aims to give our readers a better idea of how some interesting technologies we see everywhere today developed through the early years to present. Of course, we do that by telling the story through the eyes of U.S. patents.

Today, we’re taking a look at one area that has supported a tremendous amount of innovation in many fields. Without it, we wouldn’t enjoy the incredible advancements in electronics or medical procedures we have today. We focus today on clean room technologies.

As we noted in our last Evolution article, on Wednesday, May 21, 2014, the National Inventors Hall of Fame will induct its latest class of inventors into its ranks. One of these inventors to be inducted is Willis Whitfield, inventor of the modern clean room. Whitfield’s idea of a ceiling-to-floor forced-air system revolutionized the idea of the clean room and enabled incredible advancements in many scientific fields. He is being inducted posthumously into the Hall of Fame for U.S. Patent No. 3,158,457, which was granted in 1964 and was titled Ultra Clean Room. Whitfield, made the invention while working for Sandia National Laboratory, where he worked until he retired in 1984. Whitfield passed away on November 12, 2012, at the age of 92.

As with our other Evolution articles, we’ve researched the early days of air filtration systems and clean room technology to learn about how this invention develop. Early patents in the field of air filtration show us that an incredible diversity of fields have been interested in removing airborne particulates decades before clean room technologies. We’ve also featured many patents issued within the past few years which further improve clean room designs, both in terms of applications of clean rooms as well as equipment worn in clean rooms.

The Early Days of Air Filter Technologies

Through the latter part of the 19th Century, as well as the early half of the 1900s which followed, many industries started to experience an incredible need for manufacturing or operating rooms which contained very low levels of pollutants. In medical facilities, especially crowded hospitals at wartime, contaminants would cause cross-infections among patients. In manufacturing vacuum tubes and other early electronics, it was determined that the presence of dust particulate could lower the quality of the products manufactured in a facility.

Watchmakers were among the earliest manufacturers to understand the issues caused by airborne particulate in their workspaces. In some cases, watchmakers were even forced to move to more rural areas in order to complete work without having to deal with issues caused by microscopic particulate kicked up from unpaved roads. This dirt would build up on miniature components at such a level that major operational problems would occur.

Ball bearing manufacturing facilities and surgical operating rooms were other facilities that exhibited an early need for clean room technologies. The one issue to solve which serves as a common thread among innovative developers in these fields was the need for atmospheric cleanliness. Even at a couple of microns in diameter, the presence of dust was a major cause of product imperfections and issues in these and other high-tech fields going into the mid-20th Century.

During World War II, advances in air filtering technologies came mainly in the form of high efficiency particulate air (HEPA) filters. These filters could remove 99.97% of all airborne particles that measured at least 0.3 microns in diameter. Much of this early technology came from Germany, prompting America to ramp up and develop its own innovations in filters during WWII. This paper filter technology would advance in post-war years towards ultra low penetration air (ULPA) filters, which removed 99.99% of contaminants measuring 0.1 microns to 0.2 microns in diameter.

U.S. Patent No. 2058669, titled “Air Filter.”

One early patent in the area of contaminant removal was U.S. Patent No. 2058669, which is simply titled Air Filter. This patent, assigned to Staynew Filter Corporation of Rochester, NY, was granted in March 1935. It protects a panel for air and gas filtration that takes up a minimum of space and can be easily replaced when filled with dirt.

Although no specific industrial use is mentioned in the previous patent, U.S. Patent No. 2853153, entitled Military Vehicle Air Filter, protects a technology specifically designed for military tank engines. Assigned to American Air Filter Co. of Louisville, KY, in September 1958, this tank filter design includes a precleaner drawer for removing heavy particulate before it reaches the air filter intake.

Although all of these and other technologies are directed at ways of reducing airborne contaminants within various systems, none of these performed the job of total contaminant removal from a space for manufacturing, medical or scientific applications.

[Patent-Bar]

Willis Whitfield and the Clean Room

The Sandia National Laboratories in Albuquerque, NM, is a federally funded scientific research facility funded by the U.S. Department of Energy and first established in 1948. In the 1960s, development teams at this facility were involved with innovations related to maintaining high cleanliness levels within nuclear facilities.

One of these scientists was Willis Whitfield. In 1962, Whitfield developed a clean room technology that pumped air in through HEPA filters installed in the ceiling and drew air out through the floor at the bottom of the room. By using the force of gravity and a steady stream of air to propel airborne particulate to the ground, Whitfield’s system was able to keep the levels of dust and other particles to incredibly low levels within an enclosed room.

From U.S. Patent No. 3158457, entitled “Ultra-Clean Room.”

Whitfield’s invention worked so well, in fact, that many found it difficult to believe his results. However, Whitfield’s clean room technology was about 1,000 times more effective at removing particulate from the air within closed spaces. The initial enclosure couldn’t hold much more than an adult human body, but clean room systems are now capable of being scaled up to one million square feet or more in facilities manufacturing iPhone components, for instance.

The seminal patent in the field of clean room technology is U.S. Patent No. 3158457, entitled Ultra-Clean Room. Issued in November 1964 to Willis Whitfield, the patent’s description states that the invention provides air that is 100 times cleaner than air found within an air-hood worn within known clean rooms at that time. The system completely circulates air within the enclosed room at a rate of about 10 air changes per minute.

From medical facilities to research laboratories to electronics manufacturers, Whitfield’s invention found many industrial applications within just a few years. The National Inventors Hall of Fame profile on Whitfield reports that nearly $50 billion in clean room technology investment occurred within a few years of the innovation. Clean room technologies led to amazing improvements in quality for medical procedures, significantly reducing the rate of infection, as well as manufacturing, allowing companies to produce even complex machinery like engine transmissions with a much greater service life.

Current Technology in Clean Rooms

From U.S. Patent No. 8617479, titled “Foot/Footwear Sterilization System.”

Our recent search of the latest technological innovations related to clean rooms show us that development in this area of technology is still being pursued 50 years after the first clean room technology was developed, although much of the innovation deals with improved equipment for individuals working within a clean room environment.

One example of the immense number of uses for clean room technologies is featured in U.S. Patent No. 8216510, issued under the title Clean Room Food Processing Methods. This patent, assigned to West Liberty Foods L.L.C. of West Liberty, IA, protects a clean room system capable of reducing the presence of pathogens, such as listeria, within food processing plants to reduce contaminations. We also noticed an new design for a clean room floor panel detailed in U.S. Patent No. D685928, entitled Floor Panel for a Clean Room. As the images attached to the design patent show, the panel, developed by Hae Kwang Co. Ltd., is constructed of a grating that would let air pass through easily.

From U.S. Patent No. 8621669, titled “Disposable Safety Garment with Improved Doffing and Neck Closure.”

We also wanted to share some interesting patents related to clothing items designed for those working within clean room environments. U.S. Patent No. 8617479, which is titled Foot/Footwear Sterilization System, protects a system of sanitization for footwear which will enter a clean room from an outdoors environment. The system, developed by Hepco Medical LLC of Largo, FL, is designed to rid footwear of likely contaminants, such as fungi, spores, bacteria and viruses, aiming to reduce exposure to disease-causing contaminants.

Finally, we were also interested in the nonwoven neck safety garment protected by U.S. Patent No. 8621669, titled Disposable Safety Garment with Improved Doffing and Neck Closure. Issued in January 2014 to Quest Environmental & Safety Products of Fishers, IN, this piece of equipment protects wearers against radiation or other hazards that could be experienced within nuclear or scientific clean room environments.

![[IPWatchdog Logo]](https://ipwatchdog.com/wp-content/themes/IPWatchdog%20-%202023/assets/images/temp/logo-small@2x.png)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2024/04/Patent-Litigation-Masters-2024-sidebar-early-bird-ends-Apr-21-last-chance-700x500-1.jpg)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2021/12/WEBINAR-336-x-280-px.png)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2021/12/2021-Patent-Practice-on-Demand-recorded-Feb-2021-336-x-280.jpg)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2021/12/Ad-4-The-Invent-Patent-System™.png)

Join the Discussion

No comments yet.