Caterpillar Inc. (NYSE:CAT) of Peoria, IL, develops and markets a wide range of heavy machinery designed for use in construction and mining projects. Recent weeks have not been entirely kind to the American-based corporation, which recently announced that its 2015 revenue forecast was cut and that up to 10,000 employees would be laid off through 2018; the new revenue forecast of $48 billion is a 13 percent decline over last year’s revenues. The company hopes to cut 5,000 jobs by the end of 2016. The company has already announced the layoffs of 230 workers at its facilities in East Peoria, IL. There have been some analysts reporting that these job cuts reflect downturns in emerging markets like China, Brazil and oil-producing nations which have seen a slide in currency values.

Caterpillar Inc. (NYSE:CAT) of Peoria, IL, develops and markets a wide range of heavy machinery designed for use in construction and mining projects. Recent weeks have not been entirely kind to the American-based corporation, which recently announced that its 2015 revenue forecast was cut and that up to 10,000 employees would be laid off through 2018; the new revenue forecast of $48 billion is a 13 percent decline over last year’s revenues. The company hopes to cut 5,000 jobs by the end of 2016. The company has already announced the layoffs of 230 workers at its facilities in East Peoria, IL. There have been some analysts reporting that these job cuts reflect downturns in emerging markets like China, Brazil and oil-producing nations which have seen a slide in currency values.

With the nearly $1 billion drop in Caterpillar’s 2015 revenue forecast, the corporation has recently announced a corporate restructuring in its dealer and customer support divisions, including new divisions in global aftermarket solutions, marketing and digital as well as wear components & aftermarket distribution. If revenues and sales do not improve for the company through 2016, it would be the first time ever in Caterpillar’s history that both of those figures have decreased for four straight years. There has been some speculation that Caterpillar’s cost cutting measures might include moving jobs to existing production facilities in Mexico. Near the middle of September, Caterpillar was named to the Dow Jones Sustainability Indices (DJSI) for the 16th time.

Despite the issues currently being experienced by Caterpillar, the corporation still has a heavy research and development presence. It earned 488 patents from the U.S. Patent and Trademark Office in 2014, placing it 88th overall among all companies petitioning the USPTO for patents that year; this figure was an incredible 47 percent higher than Caterpillar’s 2013 U.S. patent levels. Caterpillar’s 2014 patent earnings were much greater than heavy industry rivals Deere & Company (NYSE:DE) and Komatsu Ltd (TYO:6301), organizations which earned 214 and 132 U.S. patents in 2014 respectively. In the three months leading up to this writing, Caterpillar earned 170 U.S. patents, a quarterly pace that would see them increase the amount of patents earned in 2015 if maintained. The Innography text cluster posted here shows us a good deal of innovation in locomotive and control valve technologies with some R&D focused on fuel injectors and engine speed.

Despite the issues currently being experienced by Caterpillar, the corporation still has a heavy research and development presence. It earned 488 patents from the U.S. Patent and Trademark Office in 2014, placing it 88th overall among all companies petitioning the USPTO for patents that year; this figure was an incredible 47 percent higher than Caterpillar’s 2013 U.S. patent levels. Caterpillar’s 2014 patent earnings were much greater than heavy industry rivals Deere & Company (NYSE:DE) and Komatsu Ltd (TYO:6301), organizations which earned 214 and 132 U.S. patents in 2014 respectively. In the three months leading up to this writing, Caterpillar earned 170 U.S. patents, a quarterly pace that would see them increase the amount of patents earned in 2015 if maintained. The Innography text cluster posted here shows us a good deal of innovation in locomotive and control valve technologies with some R&D focused on fuel injectors and engine speed.

[Companies-1]

Caterpillar’s Issued Patents: From Energy Recovery Systems to Autonomous Steering for Sport Fishing

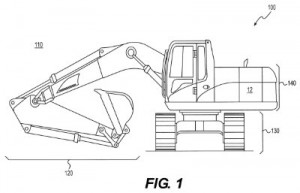

A couple of the patents recently issued to Caterpillar caught our eyes because of the regenerative energy systems that they protect. U.S. Patent No. 9086143, which is titled Hydraulic Fan Circuit Having Energy Recovery, claims a hydraulic fan circuit comprised of a primary pump, a motor, a fan driven by the motor, a flywheel configured to rotate with the fan, a supply passage extending from the primary pump to the motor, a return passage extending from the motor to the primary pump and a diverter valve that selectively connects the supply passage to a low-pressure sump. This hydraulic fan circuit used to cool equipment overcomes issues associated with conventional technologies which may recover energy from hydraulic fluid but are quite expensive currently. Regenerative braking techniques which draw power from the kinetic energy created while stopping an industrial vehicle is discussed within U.S. Patent No. 9132826, titled Energy Capture Mechanism for Electric Drive Machines. This patent protects an energy capture device having a first planetary gear assembly coupled to an engine and adapted to engage and disengage a shaft coupled to a generator and then a second planetary gear assembly partially fixed to the first planetary gear assembly and adapted to engage and disengage a shaft. This innovation intends upon improving the fuel efficiency of electric drive vehicles by facilitating high-speed energy regeneration during braking.

A couple of the patents recently issued to Caterpillar caught our eyes because of the regenerative energy systems that they protect. U.S. Patent No. 9086143, which is titled Hydraulic Fan Circuit Having Energy Recovery, claims a hydraulic fan circuit comprised of a primary pump, a motor, a fan driven by the motor, a flywheel configured to rotate with the fan, a supply passage extending from the primary pump to the motor, a return passage extending from the motor to the primary pump and a diverter valve that selectively connects the supply passage to a low-pressure sump. This hydraulic fan circuit used to cool equipment overcomes issues associated with conventional technologies which may recover energy from hydraulic fluid but are quite expensive currently. Regenerative braking techniques which draw power from the kinetic energy created while stopping an industrial vehicle is discussed within U.S. Patent No. 9132826, titled Energy Capture Mechanism for Electric Drive Machines. This patent protects an energy capture device having a first planetary gear assembly coupled to an engine and adapted to engage and disengage a shaft coupled to a generator and then a second planetary gear assembly partially fixed to the first planetary gear assembly and adapted to engage and disengage a shaft. This innovation intends upon improving the fuel efficiency of electric drive vehicles by facilitating high-speed energy regeneration during braking.

Ensuring high fuel efficiency in work vehicles is another R&D focus for Caterpillar to judge by the issue of U.S. Patent No. 9127600, titled Method and Apparatus for Generating Useful Work from the Vent Gas of a Dual Fuel Internal Combustion Engine. It claims an engine system combusting diesel and gaseous fuels which includes a diesel reservoir in communication with an internal combustion engine via a diesel rail, a liquefied gaseous fuel reservoir in communication with the internal combustion engine via a gaseous fuel rail, a pressure control device measuring the pressure differentials between the gaseous and diesel rail; if the pressure differential exceeds a desired range, the pressure control device vents gaseous fuel as fuel to an auxiliary engine for conversion into useful work. This innovation addresses shortcomings in previous dual fuel internal combustion engines which can waste gaseous fuel by venting it into the atmosphere.

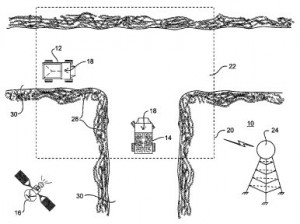

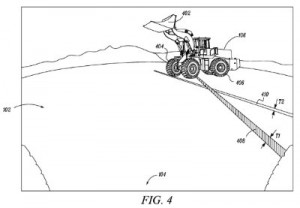

Systems for mapping certain areas of a worksite are featured within a couple of patents we found in our recent Caterpillar survey, including U.S. Patent No. 9134721, titled Worksite System Having Awareness Zone Mapping and Control. This patent claims a worksite system having an input module that receives a boundary and a characteristic of an awareness zone at a worksite, a locating device that determines the position of both a mobile machine and another mobile entity at the worksite and a controller communicating with the input module and locating device to track the mobile machine’s movement, determine the presence of the other mobile entity and initiate a collision avoidance strategy if the mobile machine enters the awareness zone containing the other mobile entity. This innovation improves upon conventional methods of preventing collisions at a common worksite which doesn’t require a user to manually define alarm zones. Methods of mapping out sloped areas of worksite are discussed within U.S. Patent No. 9097520, entitled System and Method for Mapping a Raised Contour. It discloses a system for use with a machine for generating a map of an edge of a raised contour at a worksite including a position sensing system that determines a machine’s position, a blade associated with a machine which engages material at the worksite to form the raised contour, an implement load sensor system that measures a load on the blade and a controller that determines a plurality of positions of a machine as it moves about the worksite, determines a plurality of reference points along the edge of the raised contour and generating a map of the raised contour based on the reference positions. This automated system for generating a map of changes to a worksite supports the greater use of semi-autonomous and autonomous haul machines.

Systems for mapping certain areas of a worksite are featured within a couple of patents we found in our recent Caterpillar survey, including U.S. Patent No. 9134721, titled Worksite System Having Awareness Zone Mapping and Control. This patent claims a worksite system having an input module that receives a boundary and a characteristic of an awareness zone at a worksite, a locating device that determines the position of both a mobile machine and another mobile entity at the worksite and a controller communicating with the input module and locating device to track the mobile machine’s movement, determine the presence of the other mobile entity and initiate a collision avoidance strategy if the mobile machine enters the awareness zone containing the other mobile entity. This innovation improves upon conventional methods of preventing collisions at a common worksite which doesn’t require a user to manually define alarm zones. Methods of mapping out sloped areas of worksite are discussed within U.S. Patent No. 9097520, entitled System and Method for Mapping a Raised Contour. It discloses a system for use with a machine for generating a map of an edge of a raised contour at a worksite including a position sensing system that determines a machine’s position, a blade associated with a machine which engages material at the worksite to form the raised contour, an implement load sensor system that measures a load on the blade and a controller that determines a plurality of positions of a machine as it moves about the worksite, determines a plurality of reference points along the edge of the raised contour and generating a map of the raised contour based on the reference positions. This automated system for generating a map of changes to a worksite supports the greater use of semi-autonomous and autonomous haul machines.

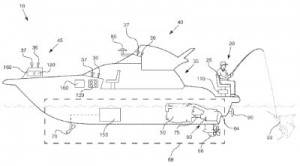

We also noted a very intriguing piece of Caterpillar IP in the field of sport fishing, which is detailed within U.S. Patent No. 9110467, titled Automatic Control of a Marine Vessel During Sport Fishing Mode. It protects a method for aiding an angler by automatically steering a marine vessel, the method involving receiving a signal in an electronic controller corresponding to the marine vessel’s orientation, receiving a signal in the electronic controller corresponding to the angle of a fish relative to the marine vessel, receiving a signal in the controller corresponding to a force applied by the fish to the vessel, determining whether the angler is engaged with the fish, calculating an error between the vessel’s orientation and the fish’s relative angle, generating steering commands for the vessel and executing steering commands so that the error is minimized. This innovative autonomous steering system is designed to improve an angler’s ability to reel in a substantial catch.

We also noted a very intriguing piece of Caterpillar IP in the field of sport fishing, which is detailed within U.S. Patent No. 9110467, titled Automatic Control of a Marine Vessel During Sport Fishing Mode. It protects a method for aiding an angler by automatically steering a marine vessel, the method involving receiving a signal in an electronic controller corresponding to the marine vessel’s orientation, receiving a signal in the electronic controller corresponding to the angle of a fish relative to the marine vessel, receiving a signal in the controller corresponding to a force applied by the fish to the vessel, determining whether the angler is engaged with the fish, calculating an error between the vessel’s orientation and the fish’s relative angle, generating steering commands for the vessel and executing steering commands so that the error is minimized. This innovative autonomous steering system is designed to improve an angler’s ability to reel in a substantial catch.

[Companies-3]

Patent Applications of Note: More Heavy Machine Automation and Augmented Reality Systems for the Worksite

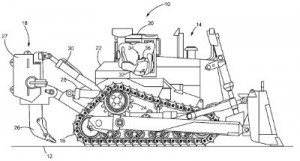

Systems for worksite automation were at the center of a collection of Caterpillar patent applications we noticed today, including U.S. Patent Application No. 20150240452, titled Shift Logic for Ground Ripping Machine. It discloses a control system for a machine having a power source coupled to a transmission including a plurality of gears, a first operator unit for generating a ripping control signal for an auto-ripping mode, a second operator unit for generating a speed select signal that changes a transmission output speed, a controller linked to the inputs to receive signals for shifting gears and activating the auto-ripping mode. This autonomous system is designed specifically for ground ripping machines which must reach a desired speed of operation before beginning the auto-ripping process. Automated dust control systems have also been pursued by Caterpillar R&D, as readers can see within U.S. Patent Application No. 20150233245, issued under the title Automatic Watering of Worksite. The method for automatic watering of a zone on a worksite by a watering truck claimed here involves identifying a boundary of the zone on a worksite, determining a position and heading of a watering truck on the worksite, detecting if the watering truck is within the zone’s identified boundary and selectively triggering spray heads based on the detection. This invention improves on conventional watering systems for worksite dust control by enabling the automated watering of specific portions of a worksite.

Systems for worksite automation were at the center of a collection of Caterpillar patent applications we noticed today, including U.S. Patent Application No. 20150240452, titled Shift Logic for Ground Ripping Machine. It discloses a control system for a machine having a power source coupled to a transmission including a plurality of gears, a first operator unit for generating a ripping control signal for an auto-ripping mode, a second operator unit for generating a speed select signal that changes a transmission output speed, a controller linked to the inputs to receive signals for shifting gears and activating the auto-ripping mode. This autonomous system is designed specifically for ground ripping machines which must reach a desired speed of operation before beginning the auto-ripping process. Automated dust control systems have also been pursued by Caterpillar R&D, as readers can see within U.S. Patent Application No. 20150233245, issued under the title Automatic Watering of Worksite. The method for automatic watering of a zone on a worksite by a watering truck claimed here involves identifying a boundary of the zone on a worksite, determining a position and heading of a watering truck on the worksite, detecting if the watering truck is within the zone’s identified boundary and selectively triggering spray heads based on the detection. This invention improves on conventional watering systems for worksite dust control by enabling the automated watering of specific portions of a worksite.

Easier systems for vehicle operation are also at the center of U.S. Patent Application No. 20150232125, filed under the title Parking Assistance System. This patent application would protect a system for assisting an operator to maneuver a first machine relative to a second machine on a worksite, the system having a display device located onboard the first machine which displays a rear view and a bird’s eye view of the first machine and a controller on the first machine coupled to the display device to superimpose a first line indicative of an axis of the first machine in a reverse gear on the image feed, determine an angle of a reference point associated with the second machine, determine a position of the second machine and superimpose a second line on an image feed which indicates an axis associated with the second machine. This parking assistance system is meant to reduce spotting time for positioning a vehicle while improving loading efficiencies.

Easier systems for vehicle operation are also at the center of U.S. Patent Application No. 20150232125, filed under the title Parking Assistance System. This patent application would protect a system for assisting an operator to maneuver a first machine relative to a second machine on a worksite, the system having a display device located onboard the first machine which displays a rear view and a bird’s eye view of the first machine and a controller on the first machine coupled to the display device to superimpose a first line indicative of an axis of the first machine in a reverse gear on the image feed, determine an angle of a reference point associated with the second machine, determine a position of the second machine and superimpose a second line on an image feed which indicates an axis associated with the second machine. This parking assistance system is meant to reduce spotting time for positioning a vehicle while improving loading efficiencies.

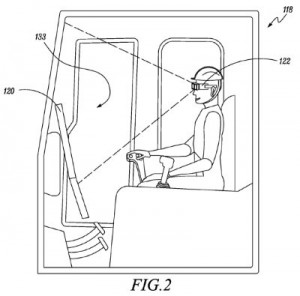

Augmented reality innovations might seem like the domain of the high tech corporations we profile in the Companies We Follow series but we found a couple of inventions in this field coming from this construction and mining equipment developer. U.S. Patent Application No. 20150199106, which is titled Augmented Reality Display System, would protect a display system for use at a worksite including a display device having a display screen, a pose sensor system that generates display device pose signals indicative of the position and orientation of the display device relative to the worksite and a controller that determines the display device’s position and orientation, generates machine control signals to control movement of a machine without an operator, generates an augmented reality image based on the machine control signals and the display device’s position and orientation, and then renders the augmented reality image on the display screen. This display system is provided to personnel at a worksite to improve safety and efficiency at a worksite using autonomous or semi-autonomous machines. A piece of wearable tech that quickly identifies the position of machine implements,  such as buckets or rippers, is at the center of U.S. Patent Application No. 20150199004, titled System and Method for Headgear Displaying Position of Machine Implement. It discloses a system for displaying the position of an implement of a machine including headgear worn by an operator of a machine and comprising a tracking sensor that generates a signal indicative of an operator’s direction of view, an image capture device that generates an image feed indicative of the operator’s field of view; the system also incorporates a controller coupled to the tracking sensor and the image capture device that receives a signal indicative of the position of a machine’s implement, overlay an outline of the current position of the implement onto the operator’s field of view and display the outline on the headgear. This innovation would be capable of providing advice to novice operators for carrying out machine operations.

such as buckets or rippers, is at the center of U.S. Patent Application No. 20150199004, titled System and Method for Headgear Displaying Position of Machine Implement. It discloses a system for displaying the position of an implement of a machine including headgear worn by an operator of a machine and comprising a tracking sensor that generates a signal indicative of an operator’s direction of view, an image capture device that generates an image feed indicative of the operator’s field of view; the system also incorporates a controller coupled to the tracking sensor and the image capture device that receives a signal indicative of the position of a machine’s implement, overlay an outline of the current position of the implement onto the operator’s field of view and display the outline on the headgear. This innovation would be capable of providing advice to novice operators for carrying out machine operations.

The fabrication of finely tuned components used in the construction of heavy industrial equipment is the focus of U.S. Patent Application No. 20150251277, titled Method of Laser Drilling a Component. This patent application would protect a method of laser drilling a component by contacting a sacrificial material with the component, aligning a laser drilling tool with the sacrificial material and the component, incidenting a laser beam on the sacrificial material, containing a trumpet effect caused by the laser beam within a thickness of the sacrificial material, forming a reverse tapered orifice in the component and removing the sacrificial material from the component. This system for manufacturing components such as fuel injectors creates orifices with reduced surface roughness, which prevents fuel from clogging while traveling through the orifice.

We’ll wrap up our survey of Caterpillar innovations with a look at one technology for more accurate estimations of noxious and polluting emissions that would be protected by U.S. Patent Application No. 20150218991, titled Exhaust Emission Prediction System and Method. This patent application claims an exhaust emissions prediction system including a catalytic device that receives a flow of exhaust, a downstream NOx sensor located downstream of the catalytic device which generates a measured value of NOx and ammonia, a controller connected to the downstream NOx sensor that determines a predicted value for the NOx sensor, determines a mass flow rate of exhaust into the catalytic device, adjusts the mass flow rate based on the predicted and measured values and determines at least one emissions characteristic using the adjusted mass flow rate. This system is optimized to provide more accurate readings for emissions of both nitrogen oxides (NOx) and ammonia; conventional sensor systems have difficulties providing reliable and accurate measurements for both NOx and ammonia in emissions.

![[IPWatchdog Logo]](https://ipwatchdog.com/wp-content/themes/IPWatchdog%20-%202023/assets/images/temp/logo-small@2x.png)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2024/04/Patent-Litigation-Masters-2024-sidebar-early-bird-ends-Apr-21-last-chance-700x500-1.jpg)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2021/12/WEBINAR-336-x-280-px.png)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2021/12/2021-Patent-Practice-on-Demand-recorded-Feb-2021-336-x-280.jpg)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2021/12/Ad-4-The-Invent-Patent-System™.png)

Join the Discussion

No comments yet.