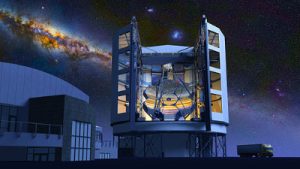

“Giant Magellan Telescope – Artist’s Concept” by Giant Magellan Telescope/GMTO Corporation. Licensed under CC BY-SA 3.0.

For centuries, telescopes of various kinds have been giving human beings on Earth a better glimpse into the surrounding universe. The use of telescopes in astronomy goes back to the days of 17th century Italian scientist Galileo Galilei who created the first instruments for the closer inspection of planetary bodies using visible light. However, these earliest telescopes used lenses, which can result in unclear images because of the inability of a lens to focus all the light it receives towards a single point.

Before the end of the 17th century, British scientist Isaac Newton created the world’s first operational reflecting telescope using a series of mirrors instead of lenses. Compared to lenses, mirrors create no chromatic aberrations as it reflects light instead of allowing light to pass through it, which would cause colors to refract at different angles. The use of parabolic mirrors, which reflect light from a curved surface, can also reduce spherical aberration by performing better than lenses at directing light to a single point. Newton’s reflecting telescope received light at a large parabolic mirror which directed light at a smaller flat mirror that could be viewed through an eyepiece.

The use of larger mirrors enabled the creation of more powerful telescopes over time. However, by the 1970s the size of the mirror itself was becoming a limiting factor on building better telescopes as larger mirrors were prone to deforming. To address this, scientists began looking at creating large mirrors for astronomical telescopes by fusing together many smaller mirrors in a honeycomb structure. This year, the National Inventors Hall of Fame inducted a new member for his contributions to the production of large mirrors for astronomical telescopes: British-born astronomer J. Roger P. Angel. This Friday, August 19th marks the 30th anniversary of the issue date of the patent for which Angel was inducted.

A Backyard Experiment Yields Better Lightweight Honeycomb Mirrors

Roger Angel’s training as a scientist took place during the 1960s at some of the world’s most renowned academic institutions, including the California Institute of Technology, where he earned his master’s degree, and Oxford University, which conferred a Ph.D. upon him. By the early 1980s, he had become part of the faculty of the University of Arizona’s astronomy department.

It was while he was living in Tucson that Angel struck upon a breakthrough leading to the production of larger telescope mirrors. Using an improvised kiln, Angel tested the properties of borosilicate glass, such as the kind that used to be sold as Pyrex, to see if the material was suitable for fusing into honeycomb structures. The techniques initially tested at Angel’s home would be incorporated at a larger scale in the laboratory facility which is known today as the Richard F. Caris Mirror Lab, which Angel founded and served as scientific director.

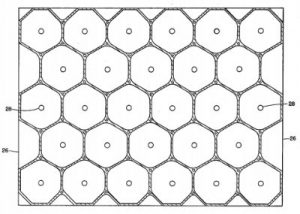

Honeycomb mirrors, which utilize a ribbed structure to support the mirror’s face, can achieve high stiffness and optical quality at a much lower weight than solid mirrors. A honeycomb mirror can be built to the same size of a solid mirror while weighing one-fifth to one-seventh less than the solid version. This enables highly cost-effective production of both the mirror as well as the support structure used to hold the mirror. Reduced mirror thickness also has the added benefit of better temperature control, discouraging convection currents from forming in front of the mirror and refracting light. The honeycomb structure is formed by pouring liquid gas into an aluminum-silica mold containing many hexagonal columns around which the glass forms; the mold is broken up with a high-pressure water spray after the glass sets. The paraboloidal face of the mirror is then milled and polished with a polishing compound to a surface accuracy which is better than 25 nanometers (nm), about the amount needed for reflecting blue light without scattering light waves.

The invention which sealed Angel’s place in the National Inventors Hall of Fame is detailed within U.S. Patent No. 4606960, titled Process for Making Honeycomb Sandwich Panels. Issued August 19th, 1986, the patent claimed a method of producing a substantially monolithic honeycomb sandwich panel structure which involves positioning a plurality of tubes in positions forming a honeycomb array of tubes wherein the tubes are in close proximity to other tubes, positioning end plates at opposite ends of each tube, heating the tubes and end plates to elevated temperatures so that the tube and end plate materials soften and form bonds, and then subjecting each tube in a heated state to gas pressure which presses softened tubes against adjacent softened tubes to form a substantially monolithic honeycomb structure. The use of gas pressure instead of sand results in a honeycomb construction method which produces honeycomb structures in a shorter amount of time than conventional methods.

The invention which sealed Angel’s place in the National Inventors Hall of Fame is detailed within U.S. Patent No. 4606960, titled Process for Making Honeycomb Sandwich Panels. Issued August 19th, 1986, the patent claimed a method of producing a substantially monolithic honeycomb sandwich panel structure which involves positioning a plurality of tubes in positions forming a honeycomb array of tubes wherein the tubes are in close proximity to other tubes, positioning end plates at opposite ends of each tube, heating the tubes and end plates to elevated temperatures so that the tube and end plate materials soften and form bonds, and then subjecting each tube in a heated state to gas pressure which presses softened tubes against adjacent softened tubes to form a substantially monolithic honeycomb structure. The use of gas pressure instead of sand results in a honeycomb construction method which produces honeycomb structures in a shorter amount of time than conventional methods.

Using Honeycomb Mirrors to Support Next Generation Telescopes

In a few short years, Angel’s production techniques were able to scale up and create larger telescope mirrors than were previously possible. In 1985, the Mirror Lab moved into a new facility on the University of Arizona campus which had a furnace capable of casting mirrors having a diameter of 3.5 meters. A furnace expansion completed in 1990 gave Mirror Lab the ability to construct mirrors with diameters as large as 8.4 meters, a feat the laboratory first achieved in 1997.

Two 8.4-meter honeycomb telescope mirrors developed by the Mirror Lab are utilized in the Large Binocular Telescope Observatory (LBTO), located in Tucson. Completed in 2004, the observatory is capable of providing the spatial resolution of a 22.7-meter telescope, classifying it as an extremely large telescope. Scientific missions carried out at LBTO include the search for exoplanets with characteristics similar to Earth as well as high redshift found throughout the universe.

The Giant Magellan Telescope (GMT) is another observatory that will utilize primary mirrors constructed at Mirror Lab. Six off-axis 8.4-meter monolith mirrors surrounding a central segment will create an optical surface which is 24.5 meters in diameter. Flexible secondary mirrors are controlled by hundreds of actuators to help counteract the effects of atmospheric turbulence which impact the performance of Earth-based telescopes. Finishing the mirrors used on the GMT requires about 50 to 80 cycles of polishing and measuring the parabolic shape, a process which can take one year to complete per mirror. As of September 2015, Mirror Lab had completed the fourth GMT primary mirror.

The lightweight nature of honeycomb mirrors also make them a good candidate for space telescopes. A honeycomb mirror structure is being used on the James Webb Space Telescope, a telescope being developed by NASA and set for launch in October 2018. It will use a 6.5-meter primary mirror constructed of 18 different mirror segments composed of beryllium. The telescope, which weighs 14,300 pounds at completion and cost $8.8 billion to complete, has five times the collecting area of the Hubble Space Telescope and will orbit the Earth at a further distance than Hubble for an even deeper look into the universe.

Over the course of Angel’s career, he has been responsible for a number of other advances in astronomical telescope development. His entry in the National Inventors Hall of Fame notes the development of ultra-thin secondary telescope mirrors for sharpened images despite atmospheric turbulence, such as is seen in the GMT design. He has also developed optical fibers for simultaneous spectroscopic analysis of galaxies which has been used to determine that dark energy is causing the universe to expand. More recently, Angel has been involved in developments surrounding the collection of solar energy using optical equipment for the creation of solar panels with high photovoltaic conversion efficiency.

![[IPWatchdog Logo]](https://ipwatchdog.com/wp-content/themes/IPWatchdog%20-%202023/assets/images/temp/logo-small@2x.png)

![[[Advertisement]]](https://ipwatchdog.com/wp-content/uploads/2023/01/2021-Patent-Practice-on-Demand-1.png)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2024/04/Artificial-Intelligence-2024-REPLAY-sidebar-700x500-corrected.jpg)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2024/04/UnitedLex-May-2-2024-sidebar-700x500-1.jpg)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2024/04/Patent-Litigation-Masters-2024-sidebar-700x500-1.jpg)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2021/12/WEBINAR-336-x-280-px.png)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2021/12/2021-Patent-Practice-on-Demand-recorded-Feb-2021-336-x-280.jpg)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2021/12/Ad-4-The-Invent-Patent-System™.png)

Join the Discussion

No comments yet.