Carbon fibers may not seem like the most exciting material in the world but it’s a material with many qualities which are preferred in a variety of industries, making the material a hot commodity in certain sectors. These fibers, which have a very thin diameter while offering high stiffness, high tensile strength and low thermal expansion, are useful in aerospace and other industrial sectors where such materials are needed to deal with high temperatures and extreme forces. According to the U.S. Department of Energy, the next generation of carbon fibers could enable the production of passenger cars which weigh 50 percent less with a 35 percent increase in fuel efficiency over today’s vehicles.

Carbon fibers may not seem like the most exciting material in the world but it’s a material with many qualities which are preferred in a variety of industries, making the material a hot commodity in certain sectors. These fibers, which have a very thin diameter while offering high stiffness, high tensile strength and low thermal expansion, are useful in aerospace and other industrial sectors where such materials are needed to deal with high temperatures and extreme forces. According to the U.S. Department of Energy, the next generation of carbon fibers could enable the production of passenger cars which weigh 50 percent less with a 35 percent increase in fuel efficiency over today’s vehicles.

In 2013, global demand for carbon fibers reached 46,500 tons, representing an annual growth rate of 8.1 percent since 2008 according to an article published in the November/December 2014 edition of Reinforced Plastics. The total value of the global carbon fiber market is expected to reach $3.51 billion in 2020 according to Markets And Markets, although the global carbon fiber reinforced plastics (CFRP) market is expected to reach $35.75 billion in the same year.

Tuesday, October 25th, will mark the 56th anniversary of the issue of the seminal patent for high-performance carbon fibers, which were invented by Roger Bacon, a 2016 inductee into the National Inventors Hall of Fame. This American physicist’s chance discovery of ultra-thin, incredibly strong fibers composed primarily of carbon led to great business success for Bacon’s employer, Union Carbide, as well as multiple recognitions of Bacon’s own work which kickstarted development into carbon materials which continue even today.

The Early Days of Carbon Discoveries and Development

According to the American Chemical Society (ACS), the modern carbon industry goes back to 1886 with the founding of the National Carbon Company. Scientific discoveries regarding the adsorbent and deodorizing qualities of natural carbon continued through the 18th and 19th centuries, but it wasn’t until the use of carbon rod arc lamps on streets in American cities in the 1800s that the material would leave the laboratory and enter widespread industrial use. Carbon arc lamps were the first widely-used electric street light and they contained two charcoal rods placed apart, between which an electric arc would travel when a charge was applied to one rod. They were cheaper to maintain than gas or oil lamps but required frequent changing of the charcoal rods, caused a loud buzzing sound while operating and posed several fire and health hazards.

Carbon was also an important player in another major development in artificial lighting. Thomas Alva Edison, perhaps America’s most successful inventor, turned to carbon filaments for use in his electric light bulb. Edison conducted his first successful experiments with the carbon filament in October 1879 using lampblack, a material composed of soot from oil lamps. Edison worked with many natural materials which could be carbonized under intense heat and settled on the use of carbonized bamboo in early commercial light bulbs.

The turn of the 20th century saw developments regarding the use of activated carbon, or carbon which has been treated in order to increase its adsorptive power. The University of Kentucky’s Center for Applied Energy Research provides a timeline history of carbon online which marks 1901 as the year that Austrian scientist Raphael von Ostrejko discovered a commercial viable method for the production of activated carbon by incorporating metallic chlorides with carbonaceous materials before carbonization and then mildly oxidizing charred materials with steam or carbon dioxide at raised temperatures. By 1911, the first activated charcoal produced using this treatment process was marketed by Austria’s Fanto Works under the brand name Eponit. Von Ostrejko is listed as the inventor on U.S. Patent No. 1362064, titled Process of Producing Decolorized Charcoal which issued in December 1920.

Roger Bacon Tries to Find Liquid Form of Carbon, Ends Up Finding Carbon Fibers

In 1956, recent PhD grad Roger Bacon joined the staff of the newly formed Parma Technical Center operated by Union Carbide, a descendent of the National Carbon Company founded in the 1800s. One of his early tasks at the research facility was to find the triple point of carbon, or the temperature and pressure level at which a substance exists in its solid, liquid and gaseous phases at the same time. Working in a carbon arc furnace, which are similar to carbon arc lamps, Bacon found that as he reduced the pressure force on vaporized carbon, it would transform directly into its solid state.

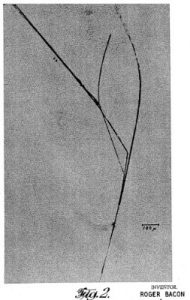

When Bacon took a closer look at the solid carbon he created, he noticed incredibly thin fibers of carbon which had a diameter smaller than a human hair but measured up to an inch in length. Further experiments showed that the material had incredible strength and stiffness. The carbon fibers produced by Bacon had a tensile strength of 20 Gigapascals (GPa) and a Young’s modulus, a measure of a material’s ability to handle a load without elongating, of 700 GPa. As the ACS notes for contrast, steel has a tensile strength of up to 2 GPa and a Young’s modulus of 200 GPa.

The patent for which Bacon is inducted into the National Inventor’s Hall of Fame is U.S. Patent No. 2957756, entitled Filamentary Graphite and Method for Producing the Same. Issued October 25th, 1960, it claimed a method for producing filamentary graphite by confining a graphite rod surmounting a carbon block within a closed pressure vessel which has a means for introducing inert gases, striking a direct current arc between the rod and the block while maintaining a pressure level within the vessel between 1,150 pounds per square inch (psi) and 1,400 psi to effect vaporization of the rod onto the block to form a boule, cooling the boule, fracturing the boule and removing the graphite filaments contained within the boule.

The patent for which Bacon is inducted into the National Inventor’s Hall of Fame is U.S. Patent No. 2957756, entitled Filamentary Graphite and Method for Producing the Same. Issued October 25th, 1960, it claimed a method for producing filamentary graphite by confining a graphite rod surmounting a carbon block within a closed pressure vessel which has a means for introducing inert gases, striking a direct current arc between the rod and the block while maintaining a pressure level within the vessel between 1,150 pounds per square inch (psi) and 1,400 psi to effect vaporization of the rod onto the block to form a boule, cooling the boule, fracturing the boule and removing the graphite filaments contained within the boule.

High-Performance Carbon Fibers are Commercialized for Defense, Aerospace

Although the discovery of carbon fibers by Bacon was tremendous for what it signaled for the future of composite materials, the production process wasn’t exactly cost-effective; Bacon estimated that it would cost $10 million to create one pound of carbon fibers using his techniques.

Within a year of Bacon’s discovery, however, other researchers at Union Carbide’s Parma facility were looking into the use of rayon as a material for creating carbon fiber. Curry Ford and Charles Mitchell patented a method of creating carbon fibers from rayon, which readers can see in U.S. Patent No. 3107152, which is titled Fibrous Graphite. In 1964, Bacon and colleague Wesley Schalamon utilized a process in which carbonized fibers were stretched at temperatures up to 2,800°C to achieve fibers with a ten-fold increase in Young’s modulus over other fibers produced from rayon, but only a step along the way towards duplicating the Young’s modulus in Bacon’s fibers.

As commercially-viable carbon fibers continued to improve their quality, they became more important in the aerospace and military industrial sectors. The National Inventors Hall of Fame entry for Bacon notes that the U.S. Air Force incorporated Union Carbide’s carbon fibers into missile nose tips, rocket nozzles and aircraft structures. Carbon fibers are still used in the production of F-22 Raptor aircraft used by the Air Force.

Today, carbon fibers are produced from one of three materials: rayon; pitch, a carbon precursor formed by heating petroleum- or coal-based materials; and polyacrylonitrile. They are found in many products which must handle extreme temperatures and forces, like aircraft brakes, space structures and reinforcements for construction material. The current state of scientific development in the field has turned towards the development of carbon nanotubes, a material which is smaller than carbon fibers by an order of magnitude with similar thermal and mechanical properties. Carbon nanotubes also possess high electrical conductivity and this September it was announced that a team of researchers from the University of Wisconsin-Madison had created carbon nanotube transistors which outperformed silicon transistors in terms of passing electrical current, a finding that has major implications for the future of carbon nanotubes in consumer electronics. It’s even surmised that Bacon perhaps created the world’s first carbon nanotubes in his 1958 discovery, even if he didn’t notice them at the time.

![[IPWatchdog Logo]](https://ipwatchdog.com/wp-content/themes/IPWatchdog%20-%202023/assets/images/temp/logo-small@2x.png)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2024/04/UnitedLex-May-2-2024-sidebar-700x500-1.jpg)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2024/04/Artificial-Intelligence-2024-REPLAY-sidebar-700x500-corrected.jpg)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2024/04/Patent-Litigation-Masters-2024-sidebar-700x500-1.jpg)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2021/12/WEBINAR-336-x-280-px.png)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2021/12/2021-Patent-Practice-on-Demand-recorded-Feb-2021-336-x-280.jpg)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2021/12/Ad-4-The-Invent-Patent-System™.png)

Join the Discussion

No comments yet.