“Drywall” by Peter Griffin. Public domain.

One of the basic components of most building construction which occurs in the United States and throughout the world involves the use of drywall. Most drywall today involves a layer of gypsum which is sandwiched between two sheets of paper and the sheets are used to create walls and ceilings in rooms. A January 2017 market research report from IBISWorld indicated that the global market for drywall and insulation installation saw annual revenues of $49 billion. According to the report, the drywall market has overcome recent declines caused by the Great Recession and increased investment in housing are expected to improve industry revenues. According to online statistics portal Statista, U.S. sales of wallboard products have increased from a recent low of 17,200 billion square feet in 2011 up to 22.5 billion square feet of products sold in 2016. A 2014 report on the global drywall market from Reportlinker forecast a 4 percent annual increase in the global demand for drywall through 2018, largely driven by rebounds in the North American and European housing markets.

Near the end of the 19th century, building construction involved a much more labor-and time-intensive method of erecting walls known as wet-plaster construction. Yesterday, May 22nd, marked the 123rd anniversary of the issue of an early and important patent covering a drywall product for building construction. Its inventor, American-born Augustine Sackett, was a 2017 inductee into the National Inventors Hall of Fame. With the anniversary of the issue of this seminal patent in the field of building construction upon us, we’ll take a look back today at the history of gypsum use across the world and how Sackett’s innovation completely changed the American home building industry.

A World of Gypsum, from Ancient Greece to 19th Century Paris

Calcium sulfate dihydrate (CaSO4·2H2O) acquired the name of “gypsum” thanks to the Ancient Greeks, who used a material they called “gypsos” in the construction of pyramids, many of which continue to stand today. Additionally, references to gypsum have reportedly been found in cuneiform tablets which remain from Assyrian cultures which existed centuries before the Ancient Greeks. Gypsum exists as a soft sulfate material which is moderately water-soluble and slightly transparent in rock form; selenite, a mass form of gypsum, also reportedly got its name from the Ancient Greeks who named the material after Selene, a Greek moon goddess, for the moon-like quality of the light transferring through the solid mass.

The formation of gypsum deposits goes back much further than these early human cultures. A major deposit found in the state of Michigan, for example, began to accumulate during the Paleozoic Era after major seawater deposits entered the Michigan Basin and then either receded or evaporated a series of six times. Gypsum formations are incredibly abundant and there is no shortage of the mineral. The White Sands National Monument in New Mexico, for example, has a gypsum dunefield which covers an area of 275 square miles.

Gypsum actually includes two water molecules for each molecule of calcium sulfate and a method for dehydrating gypsum helped to create a form of gypsum which is still used in medical fields today to make casts for broken bones. Dehydrated gypsum, created by heating gypsum to temperatures ranging from 330°F to 370°F, is known as “plaster of Paris” because the material used to be mined exclusively from the Montmartre district of Paris. The discovery of plaster of Paris in the 18th century created entirely new uses for gypsum as the material could be molded in its plaster state into a shape which would hold as the gypsum dried. Gypsum has also traditionally been used as a fertilizer to improve crop yields.

Augustine Sackett Creates Gypsum Board for Faster Building Construction

Augustine Sackett. From the National Inventors Hall of Fame website.

Not much exists on the record about Augustine Sackett, born in Connecticut in 1841 who studied at Rensselaer Polytechnic Institute in the 1850s. Census and historical data collected about Sackett showed that he served the Union in the Civil War and spent much of his life in the northeastern U.S. The last few decades of his life he spent living with his wife Charlotte and daughter Edith on Madison Avenue in New York City.

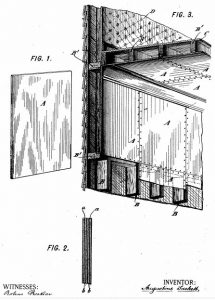

On May 22nd, 1894, Sackett was issued U.S. Patent No. 520123, titled Inside Wall Covering. The wall covering developed by Sackett was intended to serve as a substitute for lath and plaster as a material for forming the inner walls of houses or rooms. Sackett’s board was thick enough to produce a required level of rigidity for forming a firm wall surface while also being soft enough to admit nails and tough enough to avoid cracking. The wall covering required “a substance in the nature of a lime cement,” with calcined gypsum (plaster of Paris) being the most preferable cement. The plaster’s inherent brittleness was overcome by applying thin layers of gypsum alternating with layers of paper. The ‘123 patent claimed a flat board or plate for wall coverings consisting of webs of paper alternated with layers of hard adherent plastic substance.

On May 22nd, 1894, Sackett was issued U.S. Patent No. 520123, titled Inside Wall Covering. The wall covering developed by Sackett was intended to serve as a substitute for lath and plaster as a material for forming the inner walls of houses or rooms. Sackett’s board was thick enough to produce a required level of rigidity for forming a firm wall surface while also being soft enough to admit nails and tough enough to avoid cracking. The wall covering required “a substance in the nature of a lime cement,” with calcined gypsum (plaster of Paris) being the most preferable cement. The plaster’s inherent brittleness was overcome by applying thin layers of gypsum alternating with layers of paper. The ‘123 patent claimed a flat board or plate for wall coverings consisting of webs of paper alternated with layers of hard adherent plastic substance.

Sackett Board, as the drywall product was first called, reduced the time it took to construct a single home by up to two weeks as the board could be installed within a single day. In 1909, Sackett’s production plants were purchased by the US Gypsum Company which took over production of drywall. US Gypsum continued to research methods for increasing drywall production and to increase the ease of drywall use for American home builders.

It would take two different world wars in the 20th century, however, to make gypsum drywall the preferred wall building material for interior room construction. The durability and fire-resistant nature of drywall were reasons why the U.S. military chose it as a material for building rooms in barracks during World War I after a fire claimed the lives of several servicemen, according to at least the Gypsum Association. In World War II, the American military used 2.5 billion square feet of gypsum board by 1945. Lumber rationing during WWII also encouraged further use of drywall in construction and by 1955, about half of all new American homes were built with the use of drywall. Innovation has improved several qualities of drywall to make it more fire-resistant, sound-proof and pliable for curved installations. Today, more than a century after Sackett Board was patented, 97 percent of new homes utilize gypsum board during construction.

![[IPWatchdog Logo]](https://ipwatchdog.com/wp-content/themes/IPWatchdog%20-%202023/assets/images/temp/logo-small@2x.png)

![[[Advertisement]]](https://ipwatchdog.com/wp-content/uploads/2023/01/2021-Patent-Practice-on-Demand-1.png)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2024/04/Patent-Litigation-Masters-2024-sidebar-early-bird-ends-Apr-21-last-chance-700x500-1.jpg)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2021/12/WEBINAR-336-x-280-px.png)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2021/12/2021-Patent-Practice-on-Demand-recorded-Feb-2021-336-x-280.jpg)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2021/12/Ad-4-The-Invent-Patent-System™.png)

Join the Discussion

2 comments so far.

Gene Quinn

May 25, 2017 10:28 amEric-

The patent would also almost certainly be thrown into IPR after IPR over the period of many years until the inventor was willing to cry uncle.

-Gene

Eric Berend

May 25, 2017 06:25 amWere his invention to be considered for a U.S. patent today, the USPTO no doubt would inevitably reach an examination result of “obvious to combine”, in its present intensely anti-inventor zeal.