The Shell Oil Company of Houston, TX, is the American subsidiary of Royal Dutch Shell (NYSE: RDSA), one of the world’s largest and most valuable companies. The company operates thousands of gas stations across the United States and develops products for the oil & gas industry.

Shell maintains a significant investment into research and development within its own corporation. The company’s 2014 fourth quarter earnings report showed that Shell invested $428 million into R&D during that quarter, increasing their expenditures over 2013’s fourth quarter R&D costs of $363 million. During the entire 2014 fiscal year, Shell spent $1.2 billion on R&D. Decades-long investment into natural-gas-to-liquids (GTL) technologies on behalf of Shell has recently resulted in the development of a clear base oil derived from natural gas, a cleaner burning fossil fuel. Shell has also committed millions of dollars in just the past few months on educational initiatives and academic research, such as the $3.5 million it contributed to the University of Houston last October for energy and engineering education programs.

Lower prices for oil being experienced all over the world has led to lower than expected earnings for Shell, setting the stage for a volatile oil & gas market over the next year even as corporate earnings increased by 12 percent over the past year. The company has cut  or postponed many of its planned projects because of the market downturn in oil prices. In America, Shell has also been dealing with production problems because of refinery workers who have been striking for better plant safety standards.

or postponed many of its planned projects because of the market downturn in oil prices. In America, Shell has also been dealing with production problems because of refinery workers who have been striking for better plant safety standards.

During 2013, the Shell Oil Company received 189 patents from the U.S. Patent and Trademark Office, tied for 156th-overall that year with Whirlpool, Marvell World Trade and WMS Gaming. Our research with Innography’s patent portfolio analysis tools showed us that Shell was assigned 207 U.S. patents in 2014 held by Royal Shell; an additional patent in the portfolio that year comes from Shell Canada Energy for a total of 208 U.S. patents issued to Royal Shell companies that year. These patents largely focused on oil & gas processing innovations involving gas streams, hydrocarbon streams and reaction products, according to the text cluster posted here.

[Companies-1]

Shell’s Issued Patents: Sorghum Biofuels, Offshore Drilling and Harnessing Landfill Gas

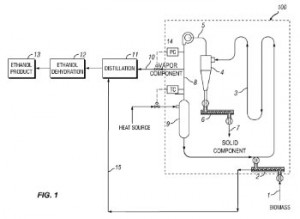

One of the most interesting aspects of our perusal of Shell’s patents issued in recent months by the USPTO is the number of technologies related to biomass conversion and biofuel production from alternative sources. The production of liquid fuels from plant biomass which are more suitable as transportation fuels or for industrial chemical processes is disclosed and protected by U.S. Patent No. 8921629, which is titled Process to Produce Biofuels Via Organic Phase Thermal Hydrocatalytic Treatment of Biomass. The method claimed by this patent involves providing a biomass feedstock of cellulose and water, contacting the feedstock with an organic solvent to form a digested biomass stream, contacting the digested biomass stream with molecular hydrogen in the presence of a metal catalyst capable of activating molecular hydrogen, phase separating the resulting hydrocatalytically treated mixture and processing a portion of the water phase to form a fuel blend with higher hydrocarbons. This process of directly converting biomass into liquid fuels achieves further net carbon savings in producing synthetic gasolines and jet fuels than conventional methods. A biofuel production  process that uses fuel crops other than corn, which is an important food resource, is at the center of U.S. Patent No. 8946491, which is titled Process for Producing Volatile Organic Compounds From Biomass Material. The patent protects a method for the recovery of a volatile organic compound from a biomass material by introducing the material to a compartment of a solventless recovery system, contacting the material with a superheated vapor stream to vaporize an initial liquid content in the biomass and then separating and retaining a vapor component containing a volatile organic compound for use as part of the superheated vapor stream. This innovation supports the production of biofuels from sweet sorghum while addressing issues of sugar content and seasonal availability. Industrially scalable procedures for cost-effectively converting biomass into fuel blends are the focus of U.S. Patent No. 8945243, titled Systems Capable of Adding Cellulosic Biomass to a Digestion Unit Operating at High Pressures and Associated Methods for Cellulosic Biomass Processing. The method protected by this patent involves providing a biomass conversion system including a pressurization zone and a digestion unit which are operatively connected, providing a cellulosic biomass at a first pressure, introducing a portion of the biomass into the pressurization zone and increasing the pressure, transferring biomass from the pressurization zone to the digestion unit after pressurization and digesting the cellulosic biomass to produce a hydrolysate with soluble carbohydrates within a liquid phase. The pressurization process established here accommodates some of the energy intensive aspects of biomass digestion while producing biofuels and other chemicals.

process that uses fuel crops other than corn, which is an important food resource, is at the center of U.S. Patent No. 8946491, which is titled Process for Producing Volatile Organic Compounds From Biomass Material. The patent protects a method for the recovery of a volatile organic compound from a biomass material by introducing the material to a compartment of a solventless recovery system, contacting the material with a superheated vapor stream to vaporize an initial liquid content in the biomass and then separating and retaining a vapor component containing a volatile organic compound for use as part of the superheated vapor stream. This innovation supports the production of biofuels from sweet sorghum while addressing issues of sugar content and seasonal availability. Industrially scalable procedures for cost-effectively converting biomass into fuel blends are the focus of U.S. Patent No. 8945243, titled Systems Capable of Adding Cellulosic Biomass to a Digestion Unit Operating at High Pressures and Associated Methods for Cellulosic Biomass Processing. The method protected by this patent involves providing a biomass conversion system including a pressurization zone and a digestion unit which are operatively connected, providing a cellulosic biomass at a first pressure, introducing a portion of the biomass into the pressurization zone and increasing the pressure, transferring biomass from the pressurization zone to the digestion unit after pressurization and digesting the cellulosic biomass to produce a hydrolysate with soluble carbohydrates within a liquid phase. The pressurization process established here accommodates some of the energy intensive aspects of biomass digestion while producing biofuels and other chemicals.

Interestingly, Shell has been investigating alternative sources of fuel feedstocks from resources other than plant crops. Landfill gases could be harnessed for the generation of energy thanks to the technology protected by U.S. Patent No. 8857212, titled Process for the Separation of Contaminant or Mixture of Contaminants From a CH4-Comprising Gaseous Feed Stream. The patent claims a method for the separation of contaminants from a CH4-comprising gaseous feed stream by passing the gaseous feed stream into and through a cold porous body with a temperature below the sublimation temperature of the contaminant and contacting the gaseous feed stream with the cold porous body to obtain a porous body with a solid contaminant or mixture of contaminants. This purification process supports the creation of useful biogas products from the gases created by anaerobic decomposition of organic waste material.

Other innovations regarding the crude oil products that Shell typically handles can be seen in U.S. Patent No. 8882995, entitled Process for Predicting and Reducing the Corrosivity of a Hydrocarbonaceous Mixture. The crude oil process claimed here involves extracting water-soluble carboxylic acids, subjecting those carboxylic acids to chromatography, calculating the carboxylic acid concentration based on the chromatography results and reducing the concentration of water-soluble non-aromatic carboxylic acids to reduce the corrosivity of the hydrocarbonaceous mixture. The patent reflects what it calls the surprising discovery that the corrosivity of crude oils can be determined based upon the concentration of water-soluble carboxylic acids, indicating that further processing steps for the crude oil is necessary.

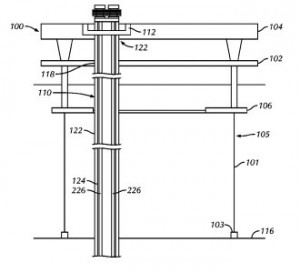

More efficient methods of offshore drilling have also been developed by Shell, as is evidenced by U.S. Patent No. 8857523, issued under the title Downhole Multiple Well. The offshore oil production system protected here includes a structure in a body of water extruding above the water’s surface, wellheads located at the bottom of a body of water and at a portion of the structuring extending above the water’s surface, a dual-bore riser extending between both wellheads, a primary wellbore extending into a subsea formation and secondary wellbores extending further into the subsea formation. This invention allows production from an increased number of wells without increasing the size of a floating offshore structure, improving production efficiency.

More efficient methods of offshore drilling have also been developed by Shell, as is evidenced by U.S. Patent No. 8857523, issued under the title Downhole Multiple Well. The offshore oil production system protected here includes a structure in a body of water extruding above the water’s surface, wellheads located at the bottom of a body of water and at a portion of the structuring extending above the water’s surface, a dual-bore riser extending between both wellheads, a primary wellbore extending into a subsea formation and secondary wellbores extending further into the subsea formation. This invention allows production from an increased number of wells without increasing the size of a floating offshore structure, improving production efficiency.

Patent Applications of Note: From Oil Recovery to Diesel Fuel Production

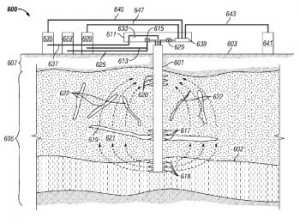

Our search through Shell’s recently filed patent applications showed us a number of oil discovery and recovery technologies being developed by the company. Hydraulic fracturing of subterranean oil-bearing formations is explained by U.S. Patent Application No. 20140360719, filed under the title Enhanced Oil Recovery Method. The patent application would protect a method of producing oil from a fractured oil-bearing formation by introducing an oil recovery formulation into a fracture within a formation of a porous matrix of rock, contacting the oil recovery formulation with the porous matrix of rock to mobilize a portion of the oil therein, contacting the mobilized oil with water or brine and producing the mobilized oil at a position upwards of the formation. This innovation is designed to increase the amount of oil produced from a fractured formation that may not be collected by a waterflood of injected water. Technology for ensuring that seismic activity created by oil discovery stays within certain parameters is discussed within U.S. Patent Application No. 20150043308, which is titled Integrated Seismic Monitoring System and Method. The integrated seismic system for monitoring seismic parameters of a subsurface structure claimed here includes a plurality of mobile satellite nodes operatively connected to sensor stations for collecting seismic data from the subsurface structure, a seismic cable connecting the satellite nodes and sensor stations and a base station with a seismic acquisition unit for receiving seismic signals from the mobile satellite nodes for generating seismic parameters. This system for integrating multiple sources of seismic data enables a more thorough analysis of that data for quality control purposes.

Our search through Shell’s recently filed patent applications showed us a number of oil discovery and recovery technologies being developed by the company. Hydraulic fracturing of subterranean oil-bearing formations is explained by U.S. Patent Application No. 20140360719, filed under the title Enhanced Oil Recovery Method. The patent application would protect a method of producing oil from a fractured oil-bearing formation by introducing an oil recovery formulation into a fracture within a formation of a porous matrix of rock, contacting the oil recovery formulation with the porous matrix of rock to mobilize a portion of the oil therein, contacting the mobilized oil with water or brine and producing the mobilized oil at a position upwards of the formation. This innovation is designed to increase the amount of oil produced from a fractured formation that may not be collected by a waterflood of injected water. Technology for ensuring that seismic activity created by oil discovery stays within certain parameters is discussed within U.S. Patent Application No. 20150043308, which is titled Integrated Seismic Monitoring System and Method. The integrated seismic system for monitoring seismic parameters of a subsurface structure claimed here includes a plurality of mobile satellite nodes operatively connected to sensor stations for collecting seismic data from the subsurface structure, a seismic cable connecting the satellite nodes and sensor stations and a base station with a seismic acquisition unit for receiving seismic signals from the mobile satellite nodes for generating seismic parameters. This system for integrating multiple sources of seismic data enables a more thorough analysis of that data for quality control purposes.

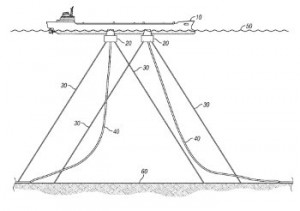

We saw advances in offshore drilling of subsea formations reflected in Shell’s recently filed patent applications, as is evidenced by U.S. Patent Application No. 20150031252, filed under the title System for Mooring a Production Vessel. The system for mooring a floating production vessel that would be protected here is made up of two or more buoys anchored to the seafloor and directly connected to the floating vessel and one or more risers connected to at least one buoy and also connected to one or more subsea wellheads. This invention does not require buoys to be connected to the floating production system through a swivel and turret system to remain aligned with prevailing weather; swivel and turret systems are expensive, especially in high temperature environments, and are prone to disconnection from icebergs or cyclonic activity.

We saw advances in offshore drilling of subsea formations reflected in Shell’s recently filed patent applications, as is evidenced by U.S. Patent Application No. 20150031252, filed under the title System for Mooring a Production Vessel. The system for mooring a floating production vessel that would be protected here is made up of two or more buoys anchored to the seafloor and directly connected to the floating vessel and one or more risers connected to at least one buoy and also connected to one or more subsea wellheads. This invention does not require buoys to be connected to the floating production system through a swivel and turret system to remain aligned with prevailing weather; swivel and turret systems are expensive, especially in high temperature environments, and are prone to disconnection from icebergs or cyclonic activity.

Shell is continuing to pursue developments in the field of biofuel production with the filing of U.S. Patent Application No. 20140343333, which is titled Process for Converting a Solid Biomass Material. This patent application would protect a process of contacting a feed of solid biomass material with a petroleum-derived hydrocarbon composition that has C7-asphaltenes in an ebullating bed reactor at a temperature range from 350? to 500?. The biomass is concurrently contacted with a source of hydrogen as well. The concurrent contacting processes yield a biofuel product which can be refined into liquid engine fuels. We were also intrigued to note a technology for increased environmental protection from the oil & gas company that would be protected by U.S. Patent Application No. 20140374105, which is titled Process for the Removal of Carbon Dioxide From a Gas. The patent application claims a process for the removal of CO2 from a gas by contacting the gas with an aqueous solution of carbonate compounds in an absorber and in the presence of an accelerator to form a bicarbonate slurry, subjecting part of the slurry to a concentration step to obtain the aqueous solution, returning the aqueous solution to the absorber, transferring a first part of the concentrated bicarbonate slurry to a first heat exchanger for heating the slurry, transferring a second part of the slurry to a different heat exchanger for heating that slurry to a different temperature, transferring both parts of the slurry to a regenerator for obtaining a CO2-rich gas and returning the regenerated carbonate stream to the absorber. This invention provides a simple and energy-efficient process for removing carbon dioxide from gases through which process solids are precipitated.

More economical methods of producing diesel fuel from feedstocks are detailed within U.S. Patent Application No. 20140339133, which is titled Two Stage Diesel Aromatics Saturation Process Using Base Metal Catalyst. The process for improving the properties of a distillate feedstock having an organic nitrogen concentration, a polyaromatics concentration and a cetane index which is claimed here involves contacting the feedstock with a first catalyst in a first reaction zone to yield a treated effluent with reduced nitrogen and polyaromatics concentrations, separating the treated effluent into heavy and lighter fractions and contacting the heavy fraction with a second catalyst, a base metal catalyst, to yield a reactor product with a distillate portion having an enhanced cetane index. This innovation results in diesel products which preferably have a higher cetane number for shorter ignition delays.

To close our survey of Shell innovations, we’ll look at a technology in the field of industrial chemical production which is explained by U.S. Patent Application No. 20140336409, entitled Process for Preparing an Internal Olefin Sulfonate. The patent application would protect a process for preparing the internal olefin sulfonate by sulfonating an internal olefin and contacting that product with a base containing solution. This process results in an internal olefin sulfonate product with a low free oil content, which is preferable for use in chemical enhanced oil recovery.

![[IPWatchdog Logo]](https://ipwatchdog.com/wp-content/themes/IPWatchdog%20-%202023/assets/images/temp/logo-small@2x.png)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2024/04/UnitedLex-May-2-2024-sidebar-700x500-1.jpg)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2024/04/Artificial-Intelligence-2024-REPLAY-sidebar-700x500-corrected.jpg)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2024/04/Patent-Litigation-Masters-2024-sidebar-700x500-1.jpg)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2021/12/WEBINAR-336-x-280-px.png)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2021/12/2021-Patent-Practice-on-Demand-recorded-Feb-2021-336-x-280.jpg)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2021/12/Ad-4-The-Invent-Patent-System™.png)

Join the Discussion

One comment so far.

Tom

April 15, 2015 03:06 pmProcesses for turning coal into methane gas appear similar, but I have not seen a working demonstration plant. Gasification of coal and waste would allow electrical generation using 70+% efficient gas turbines rather than 28% efficient steam turbines that are still used in coal & old gas power plants.

Air measurements have found huge amounts of methane coming from coal mines; it would help to recover or even burn it onsite because methane is a potent greenhouse gas around 14x worse than CO2.