Over the course of history, changes to the ways that we humans make goods which other humans can use in their daily lives have been incredibly transformative to our society. Prior to the Industrial Revolution, for example, many of the goods that people managed to make were crafted in the home but most daily needs, such as food and clothing, had to be made by people for themselves. The introduction of the steam engine and the use of special-purpose machinery allowed for much more efficient manufacturing processes to become established. The formerly agrarian societies of 18th century America and Great Britain would never be the same again, for better (a greater degree of economic involvement and an eventual dying-out of subsistence farming) and for worse (health problems caused by pollution and tough living conditions for the poor).

Over the course of history, changes to the ways that we humans make goods which other humans can use in their daily lives have been incredibly transformative to our society. Prior to the Industrial Revolution, for example, many of the goods that people managed to make were crafted in the home but most daily needs, such as food and clothing, had to be made by people for themselves. The introduction of the steam engine and the use of special-purpose machinery allowed for much more efficient manufacturing processes to become established. The formerly agrarian societies of 18th century America and Great Britain would never be the same again, for better (a greater degree of economic involvement and an eventual dying-out of subsistence farming) and for worse (health problems caused by pollution and tough living conditions for the poor).

Manufacturing in America became a bulwark of the American Dream, supporting the rise of our nation’s middle class. Whenever any discussion of income inequality or high rates of unemployment spring up, laments over the loss of manufacturing jobs over the past few decades seem to never be too far behind. Those calls prompting American citizens to “buy American” are based on the fact that a growing trade deficit has been hammering U.S. manufacturing industries and costing jobs. According to the ABC News article linked in the first sentence of this paragraph, American purchases of foreign goods has risen from 8 percent of purchases in 1960 up to 60 percent as of 2011. That same year, there were less manufacturing jobs in the country than the U.S. had during 1941.

Technological advances which have greatly increased the productivity and output of factories are certainly culpable for some of these lost jobs. However, a major new shift in the way things are made is coming and it could spark an entirely different kind of revolution. Imagine a world where an innovator comes up with a practical idea, develops a prototype and begins to manufacture goods all without ever leaving the home. It wouldn’t be the same thing as the homespun goods of the agrarian pre-Industrial Revolution but it’s still a major societal shift that we might experience in the coming years thanks to the growth of 3D printing.

The Development of Additive Manufacturing, or 3D Printing

The concept behind 3D printing, a process by which machines can construct any three-dimensional object through the use of computer coding and filaments of various materials, could be boiled down simply as “out of nothing, something.” We are familiar with manufacturing processes in which a large amount of a source material, whether wood, steel or plastic, is essentially whittled down and pared away to produce a good. The same is true of chemical manufacturing, where both organic and inorganic raw materials are subjected to chemical processes to create a chemical product. This type of manufacturing can be thought of as “subtractive manufacturing,” a process by which a raw material is provided and is subsequently formed into a product.

Additive manufacturing, which is another term that is used to refer to 3D printing, follows a very different concept: instead of using up and stripping away from a resource to form a finished good, source materials can be very finely layered on top of each other to form a product. Instead of chopping down a tree that is sawed and planed into lumber for use as a base material for furniture, a chair or table could be formed from the ground up by layering and setting a wood filament. Yes, a wooden filament would still need to be provided, but it should be fairly easy to see how resource-efficient a 3D printing process can be over traditional manufacturing.

Both the number of applications of 3D printing and the value of the industry have been growing rapidly in recent years. The 3D printing and additive manufacturing consulting firm Wohlers Associates released a study that was pretty blunt about the potential of 3D printing, which the firm predicts could become a $21 billion industry by the year 2020. Every sector of our economy and our lives, from education to healthcare to retail, could be impacted by additive manufacturing technologies.

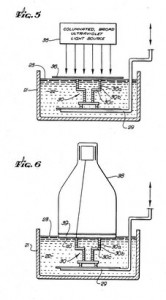

We’ve recently just experienced the anniversary of the issue of one of the seminal patents in the field of 3D printing. March 11th, 1986, is the date of issue for U.S. Patent No. 4575330, titled Apparatus for Production of Three-Dimensional Objects by Stereolithography, invented by Charles Hull and assigned to Uvp, Inc. The patent claimed a system for producing a three-dimensional object from a fluid medium capable of solidification when subjected to a prescribed synergistic stimulation to extract a three-dimensional object from a substantially two-dimensional surface. This early innovation in the field of 3D printing relied on stereolithography, a process by which a laser is projected across pools of resin to cure a cross-section layer of a product, repeating with each cross-section until the product is fully formed. This very patent earned Hull a spot in the National Inventors Hall of Fame, to which he was inducted in 2014.

We’ve recently just experienced the anniversary of the issue of one of the seminal patents in the field of 3D printing. March 11th, 1986, is the date of issue for U.S. Patent No. 4575330, titled Apparatus for Production of Three-Dimensional Objects by Stereolithography, invented by Charles Hull and assigned to Uvp, Inc. The patent claimed a system for producing a three-dimensional object from a fluid medium capable of solidification when subjected to a prescribed synergistic stimulation to extract a three-dimensional object from a substantially two-dimensional surface. This early innovation in the field of 3D printing relied on stereolithography, a process by which a laser is projected across pools of resin to cure a cross-section layer of a product, repeating with each cross-section until the product is fully formed. This very patent earned Hull a spot in the National Inventors Hall of Fame, to which he was inducted in 2014.

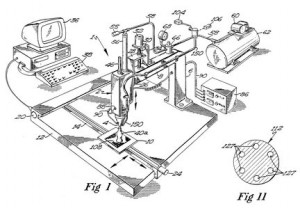

Stereolithography is by no means the only form of 3D manufacturing that has been developed. U.S. Patent No. 5121329, titled Apparatus and Method for Creating Three-Dimensional Objects, was assigned to S. Scott Crump of Stratasys, Inc., in October 1989. It protected the technology behind fused deposition modeling (FDM), which involves the deposition of layers of heated plastic filament to create an object. The FDM process is relatively cheap and doesn’t require resin but doesn’t provide a smooth finish and handles large, intricate designs poorly. More complex objects made from  a variety of materials is possible through selective laser sintering (SLS), another laser-based system of curing resins which is protected through U.S. Patent No. 5597589, titled Apparatus for Producing Parts by Selective Sintering, invented by Carl R. Deckard and assigned to the University of Texas. The SLS process is capable of utilizing a much wider array of materials, including glass and metals. It’s also a bit more prone to error than other 3D printing methods. There are still active patents in the field but these three major patents featured above have all expired.

a variety of materials is possible through selective laser sintering (SLS), another laser-based system of curing resins which is protected through U.S. Patent No. 5597589, titled Apparatus for Producing Parts by Selective Sintering, invented by Carl R. Deckard and assigned to the University of Texas. The SLS process is capable of utilizing a much wider array of materials, including glass and metals. It’s also a bit more prone to error than other 3D printing methods. There are still active patents in the field but these three major patents featured above have all expired.

One of the latest advances in additive manufacturing is an innovative process known as continuous liquid interface production (CLIP), a method of 3D printing during which a printer head is dropped into a pool of liquid resin and applies laser curing laser curing techniques that solidifies the resin as the printer head is drawn upward. Carbon3D, the company that developed the CLIP process, recently secured $41 million in venture funding capital to further develop and commercialize their system. CLIP is also many times faster than other forms of 3D printing which can require an hour or more just to complete a few millimeters’ worth of object layers.

What People Have Been Making with 3D Printers

Commercially, 3D printers are becoming a much hotter item in recent months. Our coverage of the 2015 Consumer Electronics Show in Las Vegas noted a growing trend of 3D printing systems exhibited at the industry event. The 2015 CES featured a diverse array of 3D printed objects, from clothing to candy.

It’s obvious that the novelty of additive manufacturing has not worn off for most hobbyists. When you have a machine that can craft almost any object given a properly coded design, anything from unique fashion couture to Elsa’s castle from the movie Frozen could be the result. On the other hand, the 3D printer could become a handy tool that offers a lifeline when a certain item is desperately needed. In December of last year, major news outlets picked up a story about NASA “e-mailing a wrench” to astronauts on the International Space Station. The wrench was designed on Earth, transmitted to the ISS and was printed for use by astronauts all in the course of just under one week.

There’s almost no limit to the range of practical items that could be created through 3D printing equipment. A team of chemical researchers working at the University of Illinois have created a 3D printer capable of creating small molecules less than 900 daltons in molecular weight for the manufacture of pharmaceutical agents. A similar project at Glasgow University in Scotland resulted in the development of a 3D printing process for creating a series of precise reacting chambers which could be injected with chemical reagent “inks,” also performed by the printer, for making complex molecules. Specialized 3D printing equipment has been created for fabricating dental devices such as permanent crowns and denture frames. There’s even a 3D printer designed to use filaments of graphene, an incredibly hyped substance which is essentially a two-dimensional lattice form of carbon.

There’s almost no limit to the range of practical items that could be created through 3D printing equipment. A team of chemical researchers working at the University of Illinois have created a 3D printer capable of creating small molecules less than 900 daltons in molecular weight for the manufacture of pharmaceutical agents. A similar project at Glasgow University in Scotland resulted in the development of a 3D printing process for creating a series of precise reacting chambers which could be injected with chemical reagent “inks,” also performed by the printer, for making complex molecules. Specialized 3D printing equipment has been created for fabricating dental devices such as permanent crowns and denture frames. There’s even a 3D printer designed to use filaments of graphene, an incredibly hyped substance which is essentially a two-dimensional lattice form of carbon.

3D printing doesn’t just make objects, it can create and even recreate entire cultures. One of the more interesting projects involving additive manufacturing equipment that we came across today is Project Mosul. The Middle East is dealing with a great deal of turmoil, much of which has sprouted from the increasing strength of the terrorist organization known as ISIS. This group has been doing what a lot of other craven syndicates with despicable ideologies have done over the years and has destroyed many cultural artifacts in the lands where it has managed to gain power. One of ISIS’s targets was the Mosul Museum, which housed priceless Assyrian artifacts and ancient sculptures. Project Mosul is an attempt to recreate all of the objects that have been lost in that incident, such as the Lion of Mosul and many other artifacts that were at least 3,000 years old.

Updated March 23, 2015, to correct an error in citing a source. The $21 billion in 3D printing industry revenues by 2020 statistic mentioned above comes from Wohlers Associates’ Wohlers Report 2014, not the firm previously cited.

![[IPWatchdog Logo]](https://ipwatchdog.com/wp-content/themes/IPWatchdog%20-%202023/assets/images/temp/logo-small@2x.png)

![[[Advertisement]]](https://ipwatchdog.com/wp-content/uploads/2018/10/Enhance-1-IPWatchdog-Ad-2499x833-1.png)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2024/04/Patent-Litigation-Masters-2024-sidebar-early-bird-ends-Apr-21-last-chance-700x500-1.jpg)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2021/12/WEBINAR-336-x-280-px.png)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2021/12/2021-Patent-Practice-on-Demand-recorded-Feb-2021-336-x-280.jpg)

![[Advertisement]](https://ipwatchdog.com/wp-content/uploads/2021/12/Ad-4-The-Invent-Patent-System™.png)

Join the Discussion

One comment so far.

Anon

March 21, 2015 10:57 amOn “top of” and even now “from below”…

This article caught my eye for at least one reason: this new process (limited of course to the material of the substrate) is immensely quicker – minutes instead of hours.

http://www.vox.com/2015/3/16/8227627/3d-printing-liquid-continuous

I would also offer another IP subject that represents the larger coming clash you seem to allude to: copyright and the not-so-new-anymore ability to create exact digital replicas.

Of course, the subject matter of the two differ (copyright for protecting expression and patent for protecting utility), but both are meant to protect and control “making” (or copying) and to my point both are impacted by the ability (ever growing and becoming more and more accessible) of that version of what was a science fiction “literary device” that us geeks grew up with: the Star Trek replicator.

One thing that we all should consider in the short term future: if there is the capability of “making” anything at anytime with a “generic” home machine and what many consider unprotectable pure “data,” how will the single Constitutional clause meant to protect those generating the “base items” be applied by Congress in a meaningful way to guarantee that exclusivity when the ability to violate that exclusivity is so universal, and so universally unenforceable? Even today, there are many who cry out that copyright law is simply too anachronistic to be meaningful in a digital society. This ability represented by “digital creation” moves patents (and patent law) closer back to the conundrums of copyright (and copyright law) but even more “dangerously” so, since patent law does not have the same “leniency” of copyright law in that patent law does not provide for such things as independent creation, First Amendment safeguards, Fair Use defenses or non-strict liability for infringement.

I would also mention that one of the Roddenberry visions of Star Trek was that the need for protecting “limited resources” was largely (but not universally, i.e., dilithium crystals) a thing of the past and the fact that a replicator could “whip up” most anything changed the dynamic of human interactions in an “enlightened way” was a tactic to explore that which remained “human” even in the future without focusing on the mundane.